Making a Basic Jewelry Box

Continued

P. Michael Henderson

Now it's time to fit the hinges. As I stated earlier, I'm going to use the Brusso stop hinges because they're the easiest to set.

Start by clamping the top on the bottom, making sure to get the top aligned well all around.

Placement of the hinges are up to you, but I'm going to leave 1 1/4" on each side - to the start of the hinge.

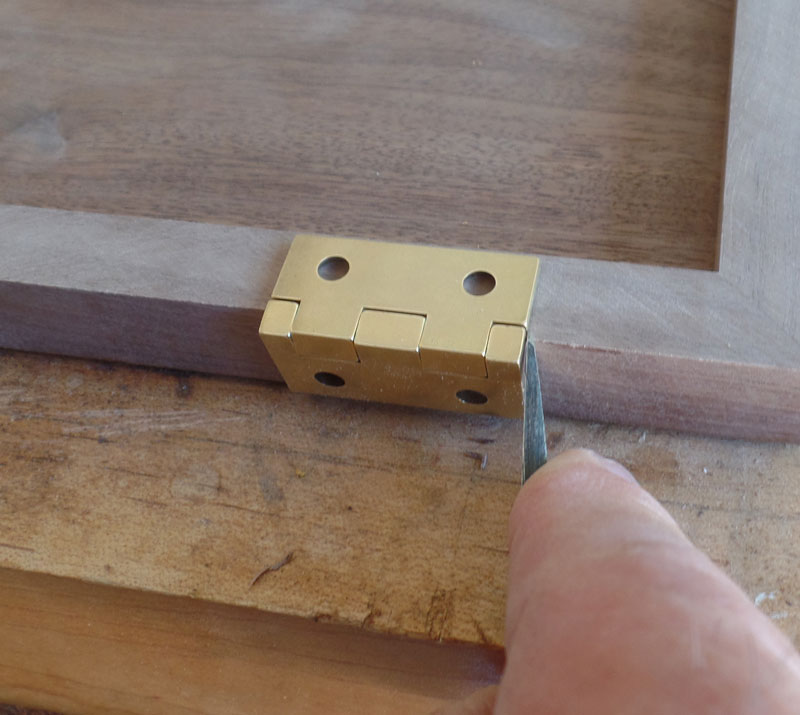

Use a knife and mark both the top and bottom at the same time.

This is what it will look like.

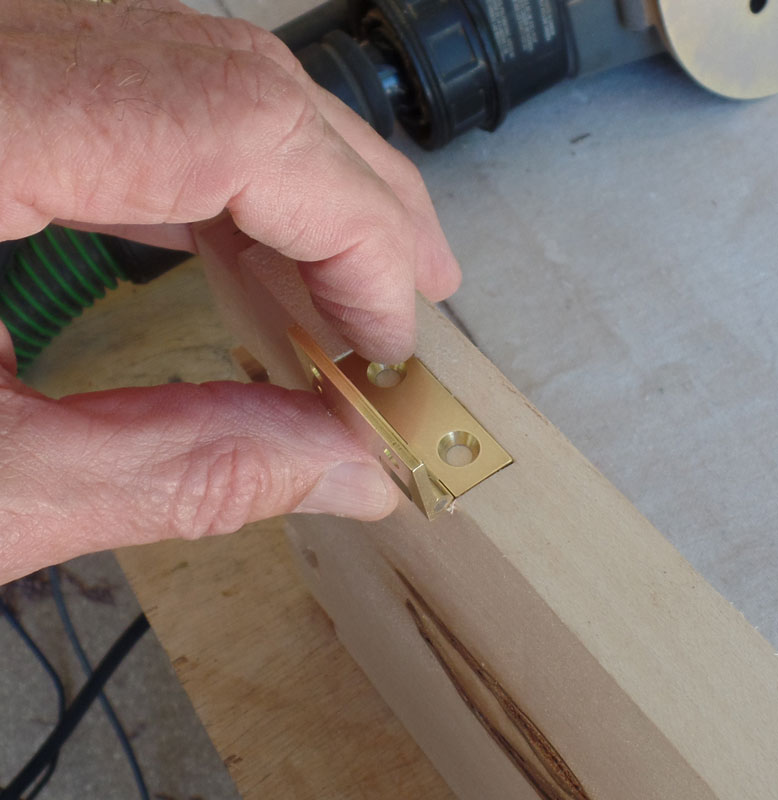

Separate the top and bottom. We'll begin work on the top. Put your knife in the mark and slide the hinge to your knife. Note that the hinge is upside down. This give you the proper spacing into the wood.

Mark all around the hinge.

You can do a hinge mortise by hand, with chisels and a router plane, or with a powered router. I'm going to demonstrate the powered router.

Before you cut into your box, set up the router on a piece of scrap. This is especially important to get the proper depth of cut.

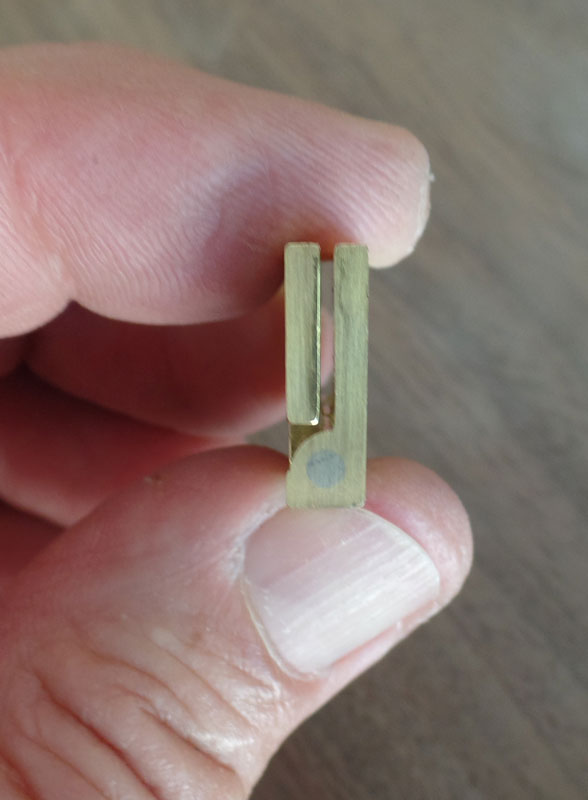

Check the depth with the hinge.

Note that hinges have what I call a "stand off distance". If you make the mortise only as deep as the hinge leaf is thick, you'll have space between the top and bottom in the rear. To correct that, you can make the mortise in the bottom deeper. But cut the original mortise only to the depth of the thickness of the hinge leaf. You can deepen the mortises on the bottom later, if you want to.

When you use the router to remove most of the waste, clean each end first before doing the center. You'll make fewer mistakes that way.

The final cleanup has to be done by hand. Start by using a chisel on the ends.

There's so little wood on the back of the mortise that I don't use a chisel on that. I just cut it with a knife. If you try to use a chisel, the wood at the back will probably break.

The remaining waste is cleaned (carefully) with a chisel

Brusso includes one steel screw with the eight brass screws. Always drive the steel screw in first to establish the threads. The brass screws break too easily. If you use hinges that don't provide a steel screw, get one that matches the brass ones and use it to establish the holes. Removing a broken screw is no fun.

To align the holes for the hinges, I use a Vix bit.

Here's how you use it. Note that I'm using one hand to hold the camera. When I actually drill the hole, I'll use one hand to push the hinge into position as I drill.

We have a problem with the top. The screws are too long. They will come out the top.

I could have tried to find shorter brass screws but instead, I just ground the ends off to shorten them. Note that I only did this for the screws that go into the top. There's plenty of room for the screws in the bottom.

Here's the top with the hinges installed.

And the bottom with the hinges installed.

And now, the moment of truth. What kind of fit do we have?

Not bad, but I had to do a bit of adjusting before I took this picture. One hinge had to be moved forward a small amount on the bottom.

Here's the box open.

Sand the outside of the box, especially the bevels on the top, and apply the solvent based poly. Here's the outside.

And the box open.

The next step is to make the tray. I usually make a tray that extends completely across the box, but this time I'm going to make a square one that will slide on the tray supports. My wife favors the full tray. Her reason: "It provides more storage."

Looking at the space I have for the tray, I have 1 1/8" from the tray support to the top of the bottom.

And 9/16" for the lip in the top, giving me 27/16" from the tray support to the inside of the top.

I'm going to use a piece of 1/4" MDF for the bottom of the tray, so that leaves me 7/8" to the top of the sides, and 23/16" to the inside of the top. I don't mind if the sides of the tray are a bit above the sides, so I'm going to make the sides 1", causing the tray to be 1/8" above the sides.

But I'm going to put in a center "handle" and that will be a bit higher.

If you have extra of the wood you made the box out of, resaw it, glue it together, mill it down to 1/4" and use that instead of MDF. The sides will still be the same as I calculated above.

I'll begin by marking the MDF and cutting it to size.

Once you have a good fit, cut the piece square using the same spacing on your table saw.

Don't try to make the fit too tight. On the first boxes I made, with full size trays, I made the tray with a tight fit. It's too hard to get out and to put back in. A less tight fit works better.

Then cut material for the sides, 1" wide. I used offcuts from the wood that I had glued together for the top. Cut it with miters, to the width of the MDF.

Cut four pieces.

Now, I'm going to work on the center "handle" part of the tray. I chose to make it 1 1/4", which means the top of it will be 1 1/2" above the tray supports. This is 24/16" which means it will not hit the bottom of the top when the lid is closed.

I have to cut a small dados in two sides. I begin by finding the center of two pieces.

Then I butt the center piece against the side and mark the edges with a knife.

Here are the two knife marks.

Using a square, I carry the knife marks down across the piece.

Then cut the dados with chisels. I have a small router plane that I use to get a flat bottom.

Check the fit of the "handle" in the dado.

Do the other side. Then sand the inside of the tray sides.

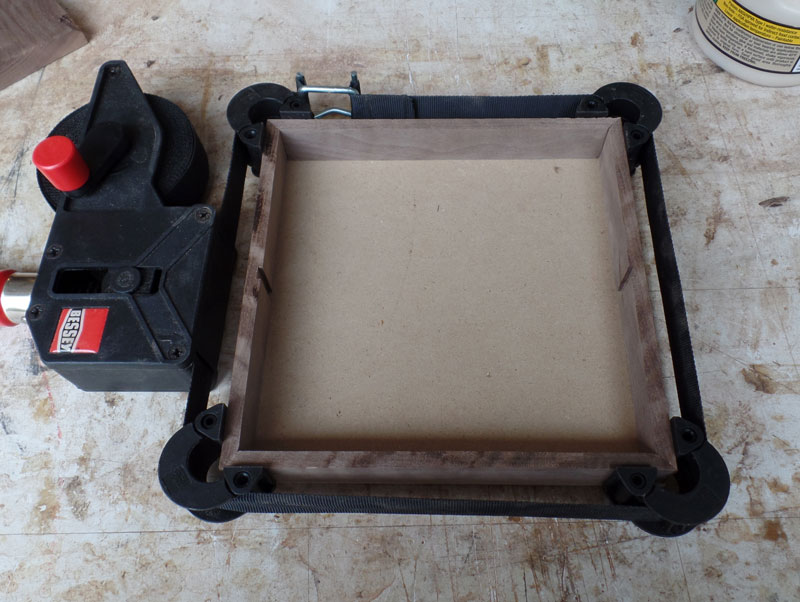

Glue-up the sides of the tray.

Here are the sides glued up. Note that they are not glued to the bottom.

Take the "handle" piece and cut it to length to fit across the tray and into the dados. Make a nice tight fit.

I'm going to drill two holes to create a "handle". I going to use a 3/4" Forstner bit for the holes. I want to leave 1/4" at the top, and the distance to the center of the holes is 3/8". When I drill the holes, I'll space them 1/4" to the side of the center line.

Here are the holes drilled.

I use a rasp to flatten out the sharp points.

Then I take the "handle" back to the tray sides and mark the depth with a knife.

I shape the handle on a belt sander by eye. You could probably cut it on a bandsaw but there's not much wood to remove and you're going to have to sand it anyway.

I'm going to use a round over bit to round over all the edges. When doing the inside of the sides, skip the dados. If you push them into the bit, you'll chew up that area.

Here's the sides and the "handle", rounded over and sanded.

Next, I'm going to glue the bottom to the sides. I do not glue the "handle" in at this time simply because it's easier to glue the bottom on without that piece. I use just a small amount of glue to avoid getting glue squeeze out on the inside. Instead of clamps, I turn the tray over and put a weight on the bottom.

After the glue is set, I glue in the "handle". Just use a small amount of glue so you don't get a lot of squeeze out, and put a clamp across the handle.

Once it's all glued up, sand the outside of the sides. Here it is all sanded and ready for finish.

And now, with finish.

You can see how it fits into the box.

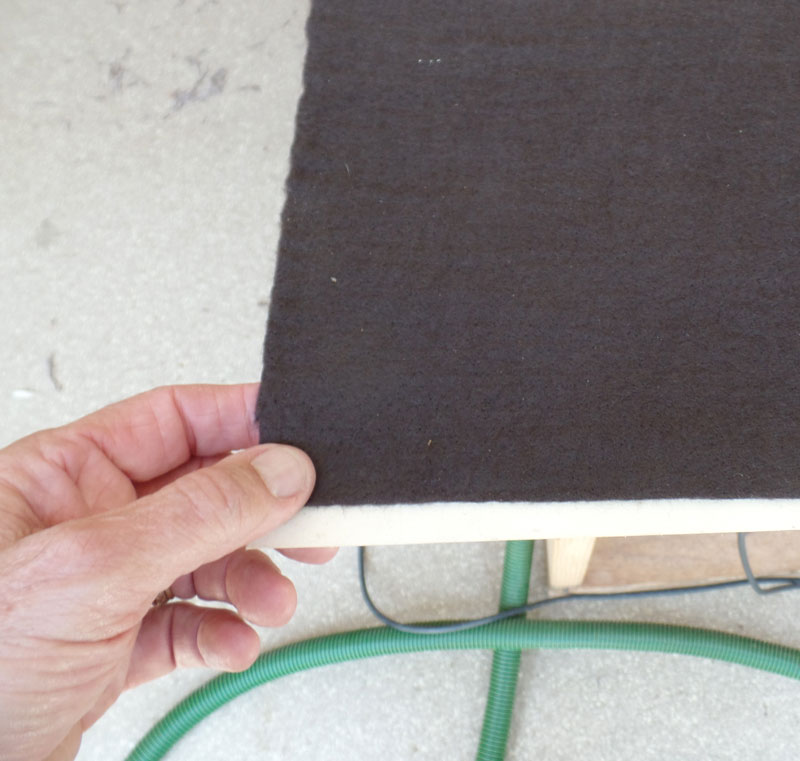

I put felt on the bottom of the box and the tray. I buy felt from a fabric store and glue it to a light cardboard with 3M type 77 spray glue.

Cut a piece to size for the bottom.

And two pieces for the tray.

Put a felt pad on each bottom corner and that finishes the making of the box.

Although I'm not showing the construction details here, I added a piece of ebony as a handle to open the box.

You can return to my woodworking here.